Main products & services:

• Level Monitoring and Valves Control System:

Our cargo monitoring and control system is a highly integrated system incorporating level gauging, temperature, pressure monitoring, valve and pump control. It takes full advantage of our large variety of reliable hardware and software modules..

Key features:

Modular design allows flexibility in configuration for the cargo monitoring and ship control system , covering the whole range of tank monitoring and tank control, as an integrated and as a stand-alone system.

Typical applications include :

> Cargo tank level monitoring

> Cargo tank pressure monitoring

> Cargo tank temperature monitoring

> Ballast tank level monitoring

> Service tank level monitoring

> Draft, Trim and List monitoring

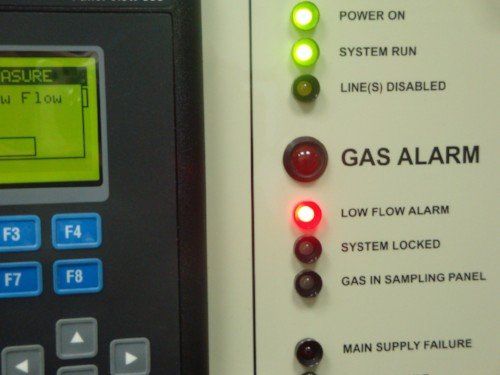

• GDS-2003/S Gas Detection System

is the new generation of sequenced sampling

gas for compartment subject to gas detection on board vessels. GDS-2003/S is robust,

easy to install, easy to use and easy to maintain, thus continuing the tradition of high

reliability already demonstrated by the previous system GDS-2003.

The GDS-2003/S is equipped for detection of explosive and toxic gases and designed to

meet the requirements of IMO/SOLAS and classification rules.

In order to minimize scanning sample time the system has two sample vacuum pumps:

Pump taking sample from all sample points continuously and other pump from the sample

Line according to the sequence. GDS -2003/S is composed in two main parts : Sampling Panel

and Monitoring panel. The two main parts can be installed in combined or split version.

General description:

GDS-2003/S is a full automatic gas detection system with PLC control unit and TFT monitor

with the following standard features :

Manual/Automatic measuring and flushing scan sequence of sample lines – Individual time

Setting of sampling/flushing for each line – Semi automatic air/gas calibration test for gas

Sensor (s) – Enabling/disabling sample lines – Adjustable set-point for gas alarm (s) – Any

Multifunction alarmed – Data-logger – System shut down for gas in Sampling Panel – Printer

(option).

Technical specification:

Main Supply : 220VAC (emergency) 50/60Hz

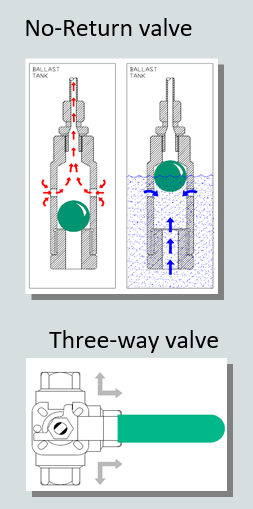

Air Supply : 6-10 bar Monitoring Panel (Particular) No-Return valve

Measurement : IR ATEX HC Sensor , 0-100%LEL (MED certified)

Electrochemical ATEX H2S Sensor 0-25p.p.m. (option)

Electrochemical ATEX O2 Sensor 0-25%vol. . (option)

User interface : TFT monitor keyboard for menu, alarm, setting, datalog

Pump : High reliability double headed vacuum diaphragm pump

Response time : Typical < 30 sec.

Sample points : Up to 48 sample points

Flame arrestors : Fitted on bulkhead for each sample line with shut-off valve

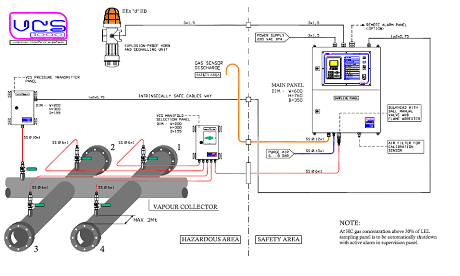

• Vapour control system (VCS-1000/1001)

The VCS‐1000(1) system has been designed in compliance with the regulations in force about the control of oxygen and pressure values of the ground return vapours.

Pressure value measurement is made on the main vapours collector, near the manifold’s detachments, by means of a pressure transmitter assembled inside a tin box and connected to the process with an stainless steel pipe , intercept valve and filter.

The value of the percentage of oxygen is measured by intaking a sample using a vacuum pump through a stainless steel pipe complete with intercept valve and filter. The intake points of vapour are located near each manifold at three meters of maximum distance from the hose attachment. The gas sample taken is transferred to the oxygen analyzer placed in the main panel in cargo control room and expelled out in the atmosphere in safe zone.

An HC gas sensor constantly controls the air inside the sample panel in order to block and power off the system in case the value exceeds 30%L.E.L.

The stainless steel pipes which take the sample of gas to the analysis panel in C.C.R. can be blow against having a pressure of 6/8 bar to eliminate possible leftovers or condensed water. A clean air intake automatically controls , every time the system is started , the calibration of the sensor that allows to go on with the sampling of the vapour line selected. It is possible to perform the control and the calibration of the HC gas sensor through the operator’s Panel using a sample gas bottle and an adapter present inside the panel. The pressure value of the collector and the manifold percentage oxygen are constantly monitored on Operator’s panel display during the normal functioning.

Possible alerts or abnormal conditions are Signaled by appropriate acoustic and optical signal.

The system provides for the possibility of an external Alarm and an option for alarm remote panel.

> Type VCS‐1000 SAMPLE LINE SELECTION THROUGH MAIN DECK MANUAL PNEUMATIC SELECTOR.

> Type VCS‐1001 SAMPLE LINE SELECTION THROUGH THE OPERATOR’S PANEL

• Draft gauging system electro-pneumatic type (Air purge EPN-40)

DRAFT GAUGING SYSTEM – Schematic diagram Experience on board ships teaches how much problem give submersed electronic level sensor due to poor durability, accuracy over time and difficult replacement.

Also known the importance for what concern draft measure that give correction to cargo tank level gauge and give very important information regarding ship condition before entering in the Port. For these cases , and others, it is proposed the installation of the sensors relative to the draft with electro‐pneumatic level gauging system type EPN‐4000 which certainly gives a guarantee of long life and accuracy on time not comparable to earlier.

The operating principle is based on the measuring the hydrostatic pressure of the liquid by providing constant low flow of air into a probe (called as sounding pipe) which opens at the tank bottom or sea chest probe on draft case. When a light quantity of air (supplied through flow regulator) is discharged on the purge mouth at the thank bottom. An air pressure corresponding to the liquid level (considering the viscosity) will be built up in the sounding pipe. The air pressure on the pipe (probe) is measure by pressure transmitter (smart technology) located on safety area and interfaced to existing or dedicated ship’s cargo supervision.

Typical applications include :

> ALL VESSEL TYPE WITH PROBLEM FOR PIEZOMETRIC ELECTRONIC SENSORS (REFITTING)

> BALLAST TANKS/DRAFT LEVEL MEASUREMENT

>ENGINE ROOM TANK LEVEL MEASUREMENT (F.O., D.O., L.O., etc)

• Marine Oxygen Analyzer (MOA-8863):

I.G.S. BACK‐UP OXYGEN ANALYZER – The 8863 oxygen analyzer allows the selective analysis of the oxygen concentration in process gases; this is due to the evident paramagnetic property of oxygen that is far different from most of the gases normally present in industrial applications. The oxygen magnetic features makes it attracted by a magnetic field (like iron magnetic materials), while for almost all other (that perform a slightly diamagnetic behavior) there is a repulsion when in presence of a magnetic field. This particular characteristic of oxygen is the base of the selectivity of this measuring principle.

Typical applications include :

> INERT GAS SYSTEM MAIN OXYGEN ANALYZER

> INERT GAS SYSTEM BACK‐UP OXYGEN ANALYZER

> VAPOUR CONTROL SYSTEM

• C.O.T. pressure monitoring system (P-VAC 300)

P‐VAC 300 – The pressure monitoring system is designed for cargo tanks pressure control for any number of tanks.

Each pressure tank is monitored every time and the system give n.4 alarm for channel measured : two alarm are for low and very low pressure condition while the other two are for high and very high pressure value. Every alarm set points can be changed by TFT monitor keyboard.

The operation principle is very easy : the pressure transmitters operate by converting changes in the piezoresistive bridge , which are proportional to the measured pressure, into a standard current or voltage output signal. The electrical signals of pressure transmitters on deck are connected to zener barriers (safety area) in the monitoring cabinet equipped with pressures alarm lamp, buzzer and display with pressure values/state in cargo control room.

The system provides installation of external alarm repeater if request (option).

Typical applications include :

> Cargo monitoring system